Toyota's original filter supporting supplier

Release time:

2024-01-08 18:02

Case Study: Guangzhou Liyinghang Composite Materials Co., Ltd. Became a Tier-1 Supplier for GAC Toyota (2021)

I. Background and Significance: Breaking Through High-End Supply Chain Barriers

As a benchmark among Japanese automakers, GAC Toyota is renowned for its stringent supplier standards. Tier-1 suppliers must pass in-depth audits covering quality systems, R&D capabilities, production management, and supply chain stability. In 2021, Guangzhou Liyinghang Composite Materials Co., Ltd. successfully obtained certification as a Tier-1 supplier to GAC Toyota, marking official recognition of its technical prowess and quality management system. This milestone laid a solid foundation for the company’s expansion into the Japanese and joint-venture brand markets.

II. Core Certification Process: Precision Alignment with Toyota Standards

1. Quality System Certification

-

Achieved ISO 45001:2018 Occupational Health and Safety Management System and ISO 14001:2015 Environmental Management System certifications, while meeting the IATF 16949:2016 standard tailored to automotive industry requirements, ensuring full lifecycle quality control.

-

Submitted PPAP (Production Part Approval Process) documents, including control plans, FMEA analysis, and full-dimension reports, demonstrating mass production capability and stability.

-

Awarded the GAC Toyota Quality Cooperation Award for three consecutive years (2022–2024).

2. Technical Capability Assessment

-

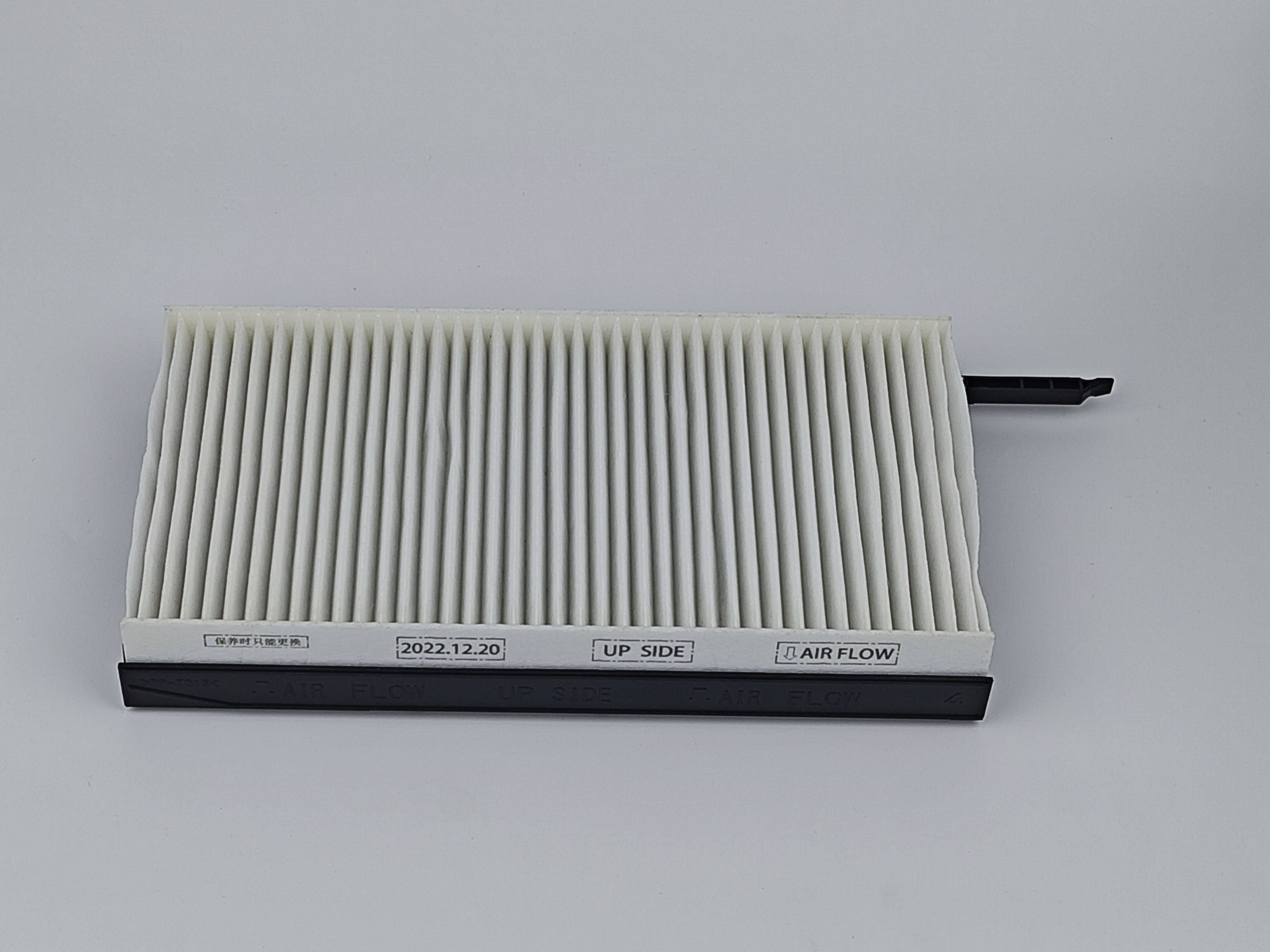

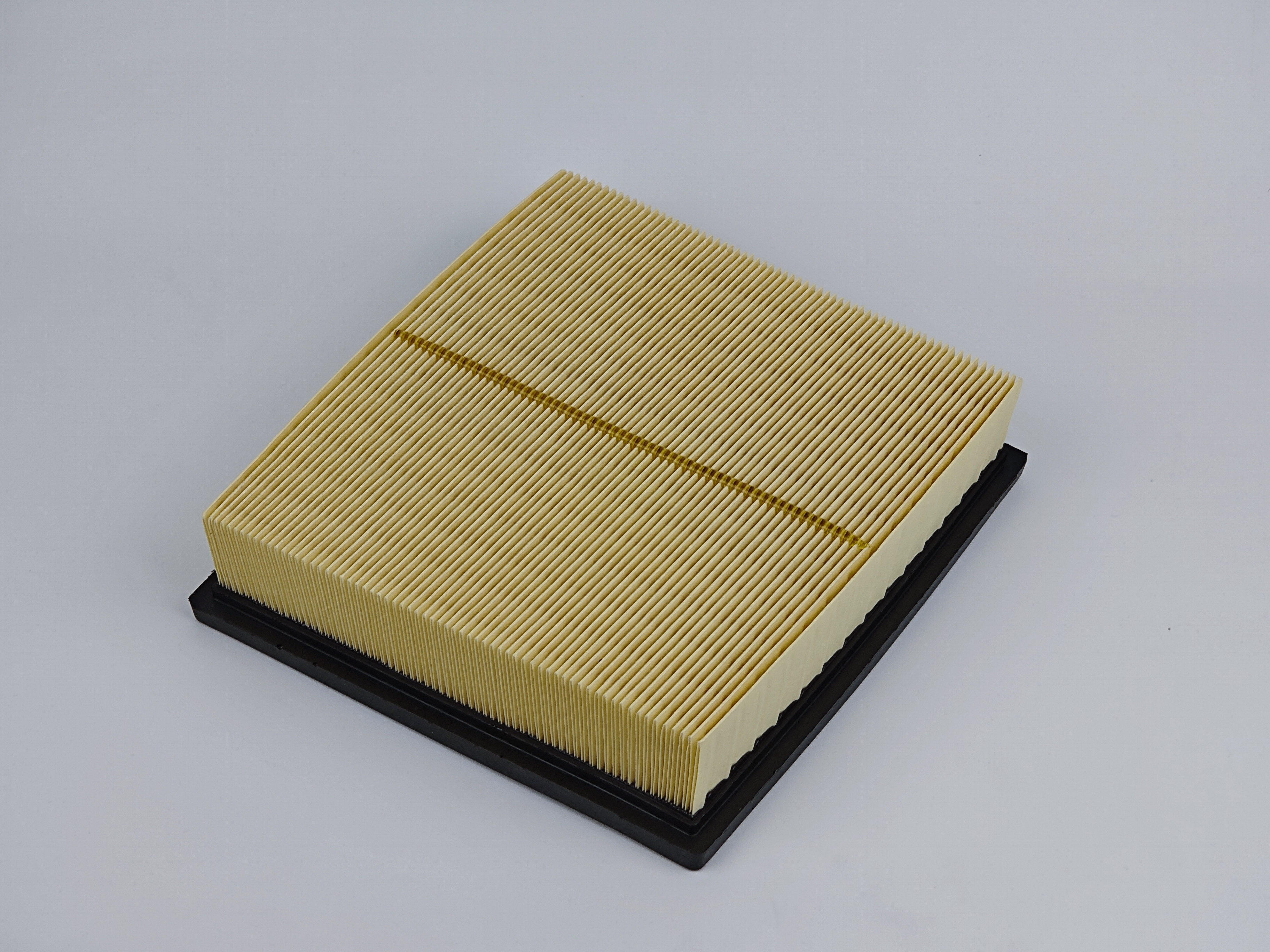

The company’s composite material products (e.g., lightweight components, interior/exterior trim) passed performance tests at GAC Toyota’s technical center, covering weather resistance, lightweight rates, and environmental indicators, with some metrics exceeding industry standards by over 10%.

-

Participated in customer synchronicity development, providing material selection and structural optimization solutions, reducing project cycles by approximately 20%.

3. Production and Supply Chain Audit

-

GAC Toyota conducted on-site factory audits covering automation levels, warehouse management, and environmental measures.

-

Established a Tier-1 supplier management system to ensure raw material traceability and risk control, aligning with Toyota’s "zero-defect" supply chain requirements.

Conclusion

By becoming a Tier-1 supplier to GAC Toyota, Guangzhou Liyinghang transformed from a "material supplier" to a "technical solutions partner." This case underscores the strategic value of driving internal upgrades through OEM standards and provides a model for Chinese component companies to break into international supply chains.